Corrosion under Insulation

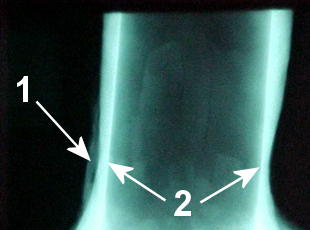

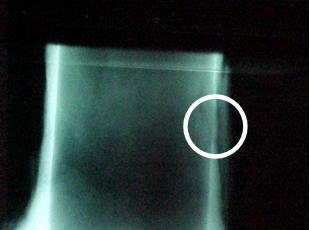

Corrosion under insulation (CUI) in piping is difficult to find because it is not immediately visible. Insulation is expensive to remove and replace. MTI uses profile radiography in pipework up to 10" diameter to gather an image of the pipe wall without removing the insulation.

When insulation is removed or had opes cut, spot ultrasonic thickness measurement is used to determine the remaining wall thickness.

Applications

In pipework systems which are susceptible to CUI such as those of carbon steel and some stainless steels some parts of the system are more susceptible to the problem than others. These areas are where insulation cladding damage exists, around elbows which are at the bottom of a riser section, in fittings and their surrounding areas where the cladding seal may not be effective and in sections where the pipe may be deluged by water or mist from other sources.

Profile radiography deployed in these areas is an effective first diagnostic tool.